In material handling, equipment is pushed to its limits every day. Crane hoppers absorb constant vibration, heavy impacts, and exposure to harsh weather. Without a strong build, that wear adds up quickly and shortens service life.

For site managers and operations leaders, a failing hopper is more than an inconvenience. It creates safety risks, drives up downtime costs, and forces unplanned replacements. In industries where schedules are tight and margins thin, those setbacks can’t be ignored.

In this article, break down the elements that determine how long a hopper lasts and explains how Lakeshore Industrial builds durability into every unit. It also explores why investing in stronger equipment pays off in both safety and cost control.

What Makes a Crane Hopper Durable?

Durability can’t be defined by a single factor. A hopper’s long-term performance depends on how it’s designed, built, and protected against the rigors of daily use. Industrial hoppers are tested in industries like construction, aggregates, manufacturing, and logistics, where abrasive materials and frequent lifts and dumps are used.

Below are the critical elements that determine whether a hopper lasts for years or wears out prematurely:

- Strength of Structure: A hopper built with heavy-duty steel frames and reinforced corners resists bending and warping even when loads shift or settle unevenly. Strong geometry and material thickness create stability across thousands of lift cycles.

- Weld Quality: Structural joints are the backbone of a hopper. When welds are weak, cracks spread quickly. Certified welding ensures each seam withstands vibration and repetitive stress without failing.

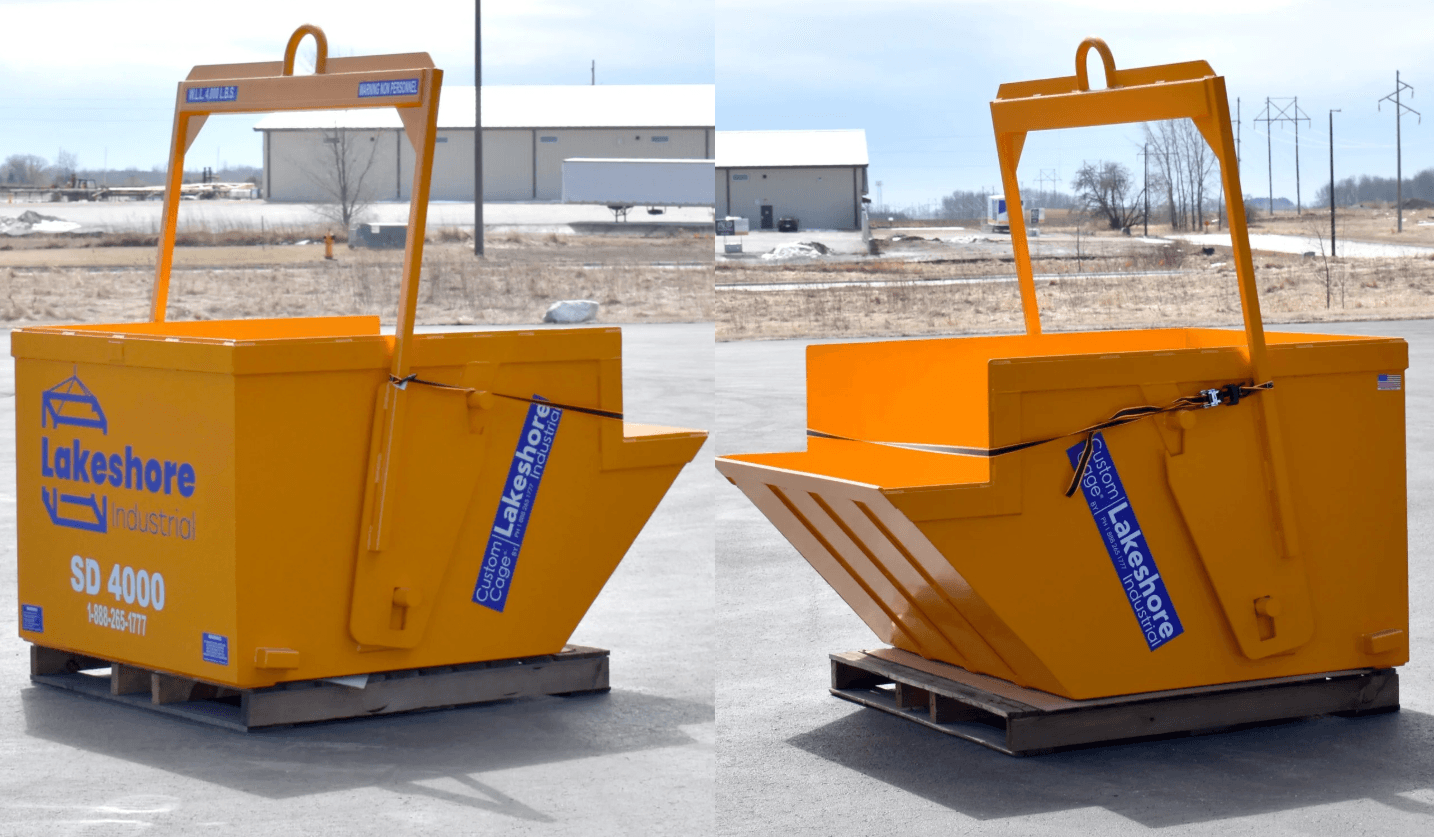

- Dumping Mechanism: The dumping system is one of the most vulnerable points in a hopper. A controlled, well-engineered mechanism reduces stress on hinges and latches. Hands-free dumping designs, such as those that avoid unhooking, help limit system wear and reduce operator risk.

- Resistance to Abrasion and Corrosion: Loads like sand, gravel, and scrap metal create impact and friction during every dump. Without adequate steel thickness or protective finishes, interior and exterior walls wear thin. Coatings, paints, or galvanization help extend service life by resisting rust and surface degradation.

- Compliance: OSHA and ASME standards form the baseline of safe design. A hopper that only meets these standards may not survive long in heavy-duty use. Designs that go beyond minimum compliance, adding reinforcements or extra load testing, are what distinguish truly durable hoppers from those that won’t stand the test of time.

Lakeshore Industrial’s Design Philosophy

At Lakeshore Industrial, our design philosophy is simple: overbuild for safety. We go beyond baseline compliance to reinforce stress points and strengthen load paths, ensuring every hopper performs for years under harsh use.

Customization plays a central role in that philosophy. No two job sites operate exactly alike, so we’re ready to tailor Lakeshore hoppers to match capacity requirements and rigging preferences. By aligning design with use case, we reduce the risks of overloading or misuse, which are among the most significant contributors to premature failure.

Every hopper is load tested and tagged before it leaves our Wisconsin facility. No product is shipped without validation of structural integrity and performance. Fabrication is also handled exclusively by certified welders, guaranteeing that joints and seams hold up to constant vibration and impact.

Material Choices & Fabrication

Durability starts long before a hopper ever reaches a job site. It begins with the selection of raw materials, the skill of the fabricators, and the checks that confirm every component will hold up under stress.

At Lakeshore Industrial, we’ve built our reputation by focusing on these details. We strive to ensure that every unit can withstand the demands of heavy lifting and repeated use.

Heavy Steel Stock

Our hoppers are built from heavy-duty plate and reinforced framing. This design endures repeated impacts from dense loads like gravel, sand, and concrete debris without buckling or deforming.

Certified Welding

Every seam is welded by trained, certified professionals who follow OSHA and ASME procedures. This level of precision ensures each joint has the fatigue resistance required for constant loading and dumping cycles.

Surface Protection

Protective finishes, whether painted or coated, form a barrier against corrosion. This helps extend the life of the steel when exposed to natural elements or abrasive materials that would quickly wear down untreated surfaces.

Inspection and Quality Checks

Quality shouldn’t stop at fabrication. Each hopper undergoes visual inspections, load testing, and detailed weld integrity verification. Bridle assemblies are built to withstand five times the working load, adding another layer of safety and strength.

Real-World Testing & Validation

Durability has to be demonstrated through testing and in the field. Lakeshore Industrial builds every hopper to meet OSHA and ASME standards for crane work platforms and under-the-hook lifting devices, establishing a consistent safety and compliance foundation.

Before any unit leaves our facility, it undergoes load testing to confirm structural integrity under expected conditions and ensure each hopper is fully certified and tagged for jobsite use.

Field performance provides the final validation. Contractors have used our skip pans and self-dumping hoppers on jobs where dump trucks cannot reach, including tight construction zones and rugged terrain. In these environments, reliability is non-negotiable, and Lakeshore equipment continues to perform without disruption.

With our compliance with standards and proven results in demanding conditions, Lakeshore hoppers have become a trusted solution for projects where failure is not an option.

The Lifecycle Cost Advantage of Lakeshore Hoppers

The true measure of a hopper isn’t only how it performs today but how it holds up over years of service. Short-lived equipment quickly erodes budgets through repeated purchases, repairs, and downtime.

By contrast, Lakeshore Industrial’s durable hoppers extend value far beyond the initial investment.

Lower Replacement Frequency

Our crane hoppers are built to endure years of heavy cycles, eliminating the constant “buy cheap, replace often” approach that drains resources.

Downtime Savings

When a hopper fails, lifting operations stop. By extending service life, Lakeshore reduces costly interruptions and keeps schedules on track.

Warranty Confidence

We stand behind our products with an industry-leading warranty: three years for man baskets and two years for material cages, including hoppers. This coverage reflects confidence in the long-term reliability of our self-dumping bins.

Maintenance & Support Services

Even the most heavy-duty hopper bins benefit from inspection and proactive support. Lakeshore Industrial designs with maintenance in mind, so operators can keep equipment safe and ready without added complexity.

Ease of Inspection

Each hopper is engineered for accessibility, allowing daily jobsite inspections to be completed quickly. Clear access points mean operators can spot wear or damage before it leads to costly downtime.

Service Support

Fast response is part of our commitment. Customers receive quotes within eight business hours, and most orders ship in less than four weeks. With us, you can avoid long waiting periods and keep projects on schedule, even when unexpected needs arise.

Inspection Guidance

Operators receive clear instructions to log inspections and only re-certify when modifications are made. This simplifies maintenance obligations and keeps compliance manageable.

Addressing Common Objections or Misconceptions

It’s natural to scrutinize options when evaluating purchases. That scrutiny is healthy, but it is important to separate assumptions from facts to make informed choices. Here are some of the most common objections raised when considering heavy-duty hopper bins:

“They’re all basically the same: a steel box with a hook. Why pay more?”

Although hoppers may look alike on the surface, differences in steel thickness, weld quality, and dumping mechanisms determine their longevity. A hopper built with a thinner plate may cost less upfront, but replacement costs quickly add up once it bends or cracks.

“Custom/overbuilt means slower delivery and higher cost.”

Our quoting process at Lakeshore Industrial delivers responses in eight business hours, and most custom builds ship in less than four weeks. Tailored designs also prevent misuse, which reduces unplanned expenses over time.

“Self-dumping mechanisms fail more often than static bins.”

Failure often comes from poorly engineered hinges or latches. Our self-dumping hoppers use reinforced pivot points and smooth-action latches designed for repeated cycles. This design improves operator safety while extending service life.

“We don’t have the lifting/rigging gear for ‘premium’ bins.”

Lakeshore Industrial builds compatibility into every design. Standard rigging gear works seamlessly, so no specialized equipment is needed to upgrade to durable hoppers. No gear is needed for our hoppers beyond the crane and its hook.

“Heavy-duty bins are overkill for many jobs.”

Conditions on jobsites can change quickly. Investing in industrial hoppers that can handle heavier loads ensures equipment is ready for future demands, reducing replacement purchases and unexpected downtime.

Strengthen Your Operations With Durable Lifting Solutions

For decision-makers, equipment durability is directly tied to outcomes. When hoppers fail, the result is downtime, safety risks, and unexpected costs. To get long-term value, you want to prioritize factors like meticulous construction and designs that comply with OSHA and ASME standards.

These qualities set Lakeshore hoppers apart, providing reliable performance where others fall short. Our heavy-duty hopper bins are built by skilled welders and tested to exceed industry requirements. With our commitment, you can count on our crane hoppers to deliver consistent performance across the most demanding environments.

Connect with us to explore specifications or request a design that fits your operational needs. You can also review related resources on crane man baskets and crane material baskets to support your next procurement decision.